Work Process Technology

- SORTING

- DECANNING

- CRUSHING

- SAMPLE, METAL ASSAY & TESTING

- SMELTERING

SORTING

The goal of our sorting process is to sort our pollutants from the valuable raw components. Different catalytic converters have different value levels. The grading of different makes, models and sizes can only be done be an experienced professional with an indepth knowledge of the recovery values.

DECANNING

Typically we will shear the stainless steel case of the converter open and release the bead or honeycomb biscuit. Since a lot of the recovery is in the platinum coating on the ceramic catalyst material it is important to collect all the dust and small pieces that are contained. We use a dust extraction system to ensure a clean and efficient operation with no metal escaping in the extraction process.

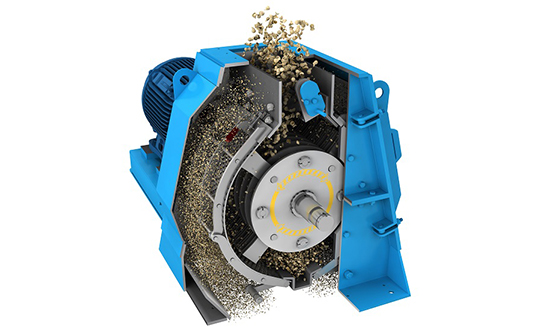

CRUSHING

The material is first crushed in compactors so it can be handled on a conveyor belt easily. A hammer mill will shred the metal into smaller pieces, shredded metals can then be placed into magnetic drums that separate the ferrous and non-ferrous metals with non-metallic materials such as paint or plastic removed by hot air and suction.

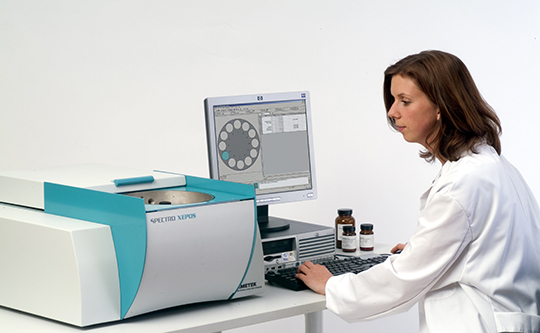

SAMPLE, METAL ASSAY & TESTING

The only accurate method to determine the precious metal content of any given load of converters is at the pre-smelter stage, by sampling and assaying the load. An assay is any test to determine the amount and type of precious metal in a sample. We can test the authenticity of the precious metal content – reliably and non-destructively using electrical conductivity or X-ray fluorescent (XRF) technology this includes our mobile handheld analyzers which give us precision readings within minutes.

SMELTERING

Our strategic partners use “Plasma Furnace Smelting Technology”. These furnaces are transforming the industry as they ensure state-of-the-art recycling with full recovery of al precious metals in a sustainable and efficient manner. Their intense and sustained energy transforms materials into their constituent atomic elements in the case of copper, gold, platinum and silver the recovery rates are typically close to 100 per cent.